When 55inch OLED TV below US$ 1,000 will be realized?

At an analytical seminar on market entry potential of OLED and Solution Process OLED having been held in Small& Medium Business Center on October 14th, Manager Jeong Seong-jin of DuPont had time of introducing tendency regarding soluble OLED material and contents of the latest development.

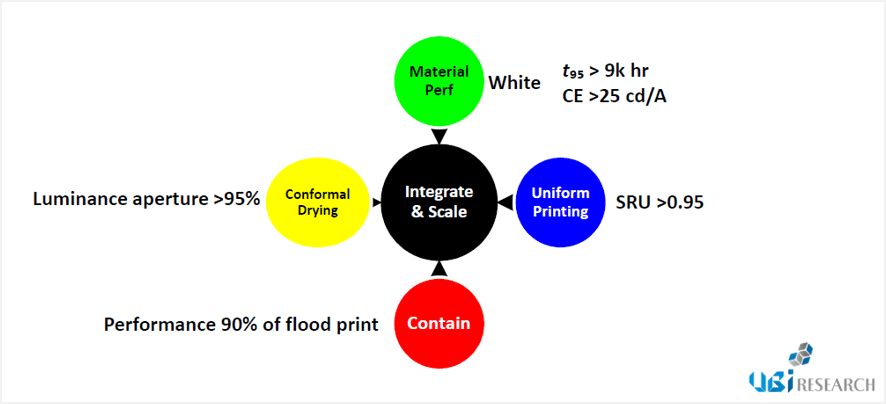

Manager Jeong said that soluble OLED material and processing technology were on the verge of completion, but problems about how to complete Solution Process by combining it was still remained as issues, and also stated that Material performance (T95>9k hr, CE>25 cd/A) and Uniform printing (SRU>0.95), Contain (performance 90% of flood print), Conformal Drying (luminance aperture>95%) would be key elements.

<4 key elements to make commercialization of Solution Process>

Dupont progressed R&D on Solution Process previously by utilizing Nozzle Printing method that used Surface Energy Modification. This method had merits such like controlling quantity was easy and the nozzle was not clogged up due to constant supply of solution, there were limitations according to panel material together with a lot of raw material consumption.

Dupont lighted up a fact that R&D has been progressed to the direction of deposing organic materials after forming Bank with Ink Jet Printing method owing to such problems and Ink Jet market having been enlarged recently, and then opened Ink Jet Material performance.

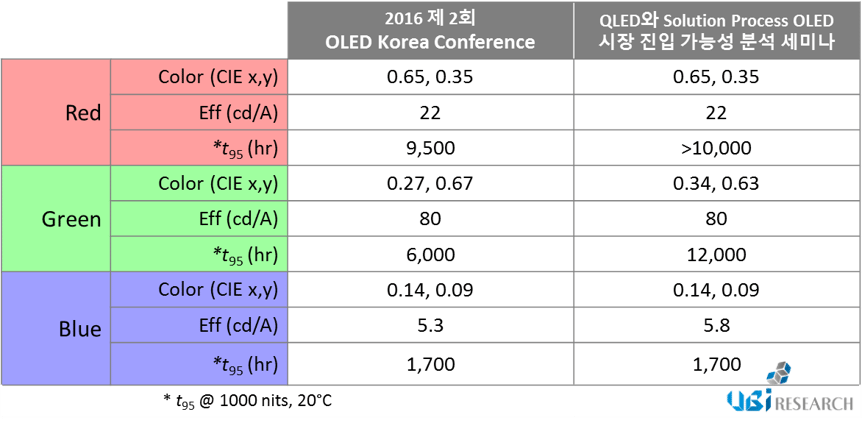

When comparing with datum pronounced in 2016 2nd OLED Korea Conference by Dupont, the life seems to be developed for Red and Green in priority, and efficiency for Blue. Approximately 6% of Red life and two times of Green were improved, and about 10% of Blue efficiency was turned out to be increased.

Manager Jeong Seong-jin put emphasis by saying “In order to expand market to OLED from display market having been enlarged gradually, adoption of Solution Process is essential, and concentration for developing soluble OLED luminescence material will be made so that 55inch OLED TV below US$ 1,000 could be produced massively until 2020 by using Solution Process in set makers.”

<Performance comparison with existing Ink Jet material of DuPont>