[Expert Talk] Interview with SAES Group’s Dr. Mauro Riva

Dr. Mauro Riva, SAES Group’s OLED/OLET business developer, kindly answered a few questions regarding OLED for OLEDNET. He will be speaking at the 2nd OLED KOREA Conference (February 24-25, 2016) in Seoul, Korea.

With much thanks to Dr. Riva for taking the time to answer some questions, here is the full script of the interview.

- What is your personal opinion on OLED’s marketability?

I believe that OLEDs have just to leverage on their unique, distinctive properties, in order to enable brand new market segments, rather than entering competition in already crowded and established markets. I mean that the specificities of organic materials make them the only candidates for creating an entire future portfolio of portable, flexible, feather-light and, possibly, low power high definition display devices.

Thus, the ability to generate really new, fancy, conformable and sustainable displays is, in my opinion, the first ingredient to boost OLED’s marketability. The second ingredient could be, in the long run, lower raw material and manufacturing costs, with respect to competing display technologies.

- Is there a particular reason for your choice to speak at the OLED specific conference rather than a more general IT conference?

As an advanced materials Company, SAES Group have developed a comprehensive portfolio of functionalized polymer composites, to be integrated in a plurality of OLED device architectures. For this reason, an OLED specific conference is the perfect place to directly discuss the important theme of encapsulation, with the people working everyday on this peculiar technology. We wanted to have a direct and frank debate with scientists and technicians specifically involved in OLEDs, rather than in general IT themes, in order to be far more focused on the manifold organic diode encapsulation issues.

- What are the latest issues on OLED encapsulation?

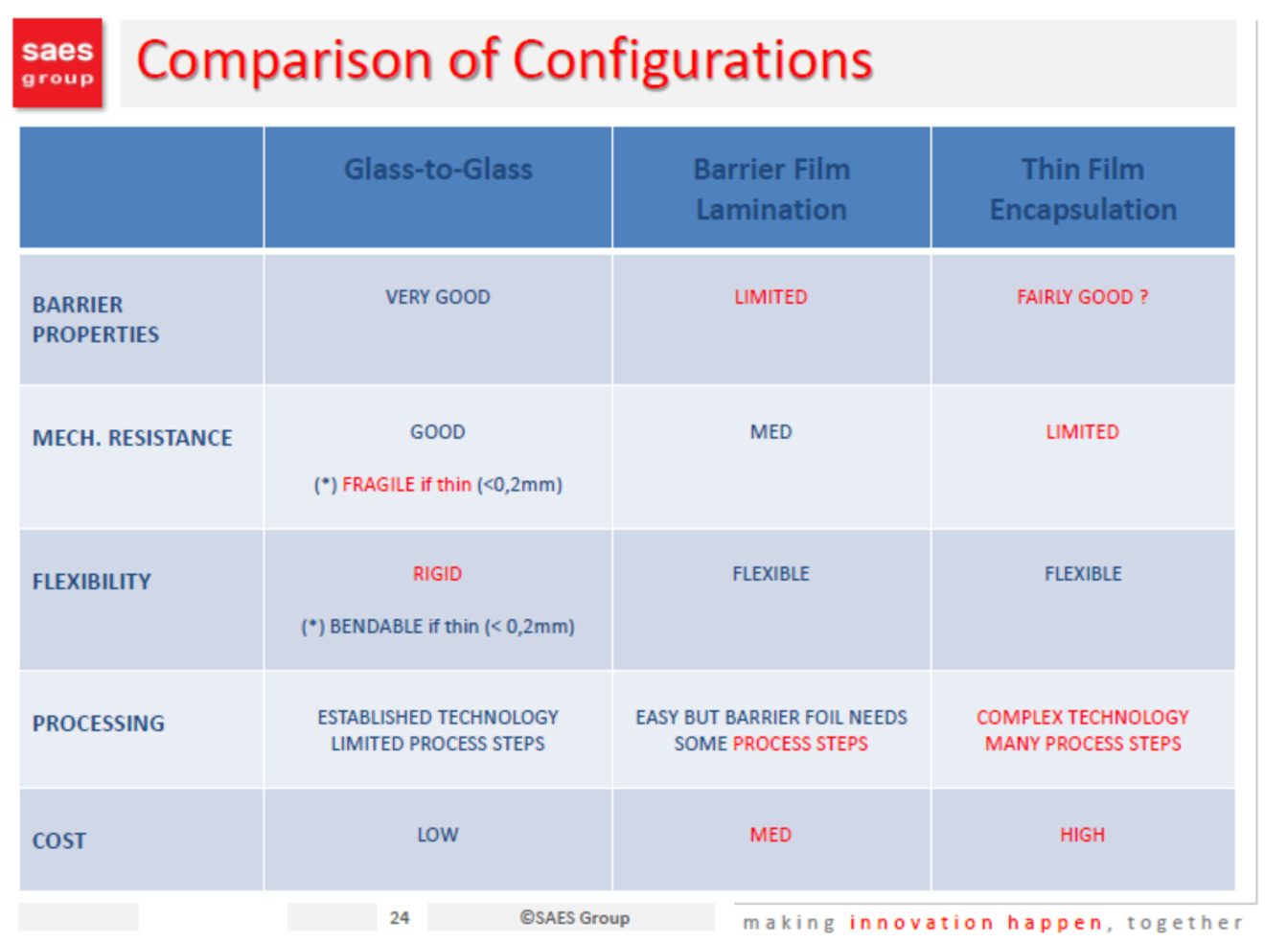

I think that OLEDs are nowadays facing the same issues they had since the beginning: basically, OLED materials are extremely sensitive to oxidizing agents and, especially, to moisture. This requires encapsulation materials with exceptionally high barrier properties, and active fillers or getters, capable of absorbing water on a single molecule basis. The optimization of many functional properties in single encapsulating materials is a very complex materials science problem. The fact that OLED materials can also be very sensitive to heat or radiations, generates many process constraints as well.

It turns out that encapsulation materials must be specifically engineered taking into account the OLED structure, the device architecture, the chemical and physical nature of the materials and, nevertheless, the specific processes to be applied. Perfecting OLED encapsulation is thus a very challenging task, which requires deep technical interaction between advanced encapsulation materials providers and OLED makers.

- Could you tell me about development concept and characteristics? Also perhaps recent performances and outcome?

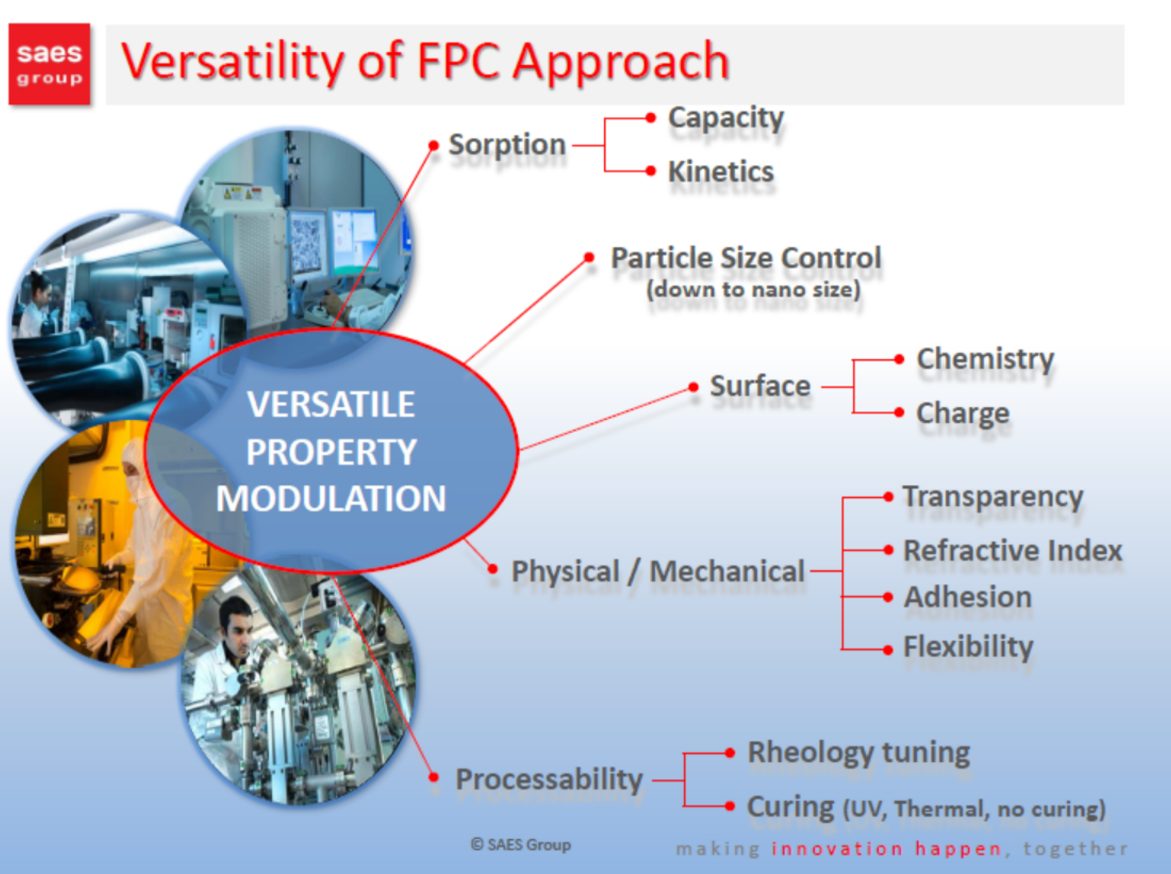

As far as the Organic Electronics Business Development Area is concerned, we provide a very large portfolio of active edge sealants, active transparent fillers, dispensable getters. These products come as the result of our deep know-how in functional polymer composites, and they are specially tailored to address customers’ specific OLED designs and processes. Leveraging on our functional polymer composite technology, we have been able to develop solventless formulations, with water sorption capacities exceeding 13 percent in weight and very high flexibility and adhesiveness for fully bendable devices. Our products can be applied via screen printing, blading, syringe, ink-jetting, ODF and even be employed in thin film encapsulation structures, to make them simpler and more reliable.

Together with the functional polymer composite based products, we also provide high performance tape dryers, as thin as 110 microns, for R&D and small scale bottom emission OLEDs. Another important class of products is related to AlkaMax: this technology offers an efficient and safe method of depositing ultrapure alkali metals. Our alkali metal dispensers and pills keep the alkali metal pure in the form of a stable salt, until it is thermally activated in the evaporation chamber.

- What are OLED related main manufacturing equipment type and who are your main clients?

We see syringe dispensing as one of the main methods for dispensing our functional polymer composites. Ink-jetting is also becoming more and more widespread, together with ODF, especially for active fillers. As of today, we get the most revenues in this field from PMOLED makers. The AMOLED market is broadening, and we have some very good customers there as well, who are especially in need of effective solutions for smartphone and tablet size high definition displays. OLED lighting is still early stage, but we are already collaborating with the major players in that field, so far at R&D or pre-production stage. The main market for our products for the organic electronics market is indeed Asia.

- Are there any areas where you are collaborating with material companies?

We have many collaborations worldwide, with other material companies as well. Regarding the functional polymer composite technology, we are collaborating in the areas of organic electronics, specialized food packaging and gas barrier films.

We are also engaged in very fruitful collaborations with specialized equipment makers.

- Is there anything you would like to add?

I would just kindly invite everyone who is interested in OLED encapsulation to visit our website and to directly contact us, for deepening all the technical aspects about our product portfolio.

The proactive and collaborating approach with our customers and the Research and Innovation focus have always been the heart of our Company way of doing: the OLEDs world offers us a real exciting and challenging arena for making innovation happen, together with all the players involved in this fascinating emerging technology.