Reporter : Hana Oh(HanaOh@ubiresearch.com)

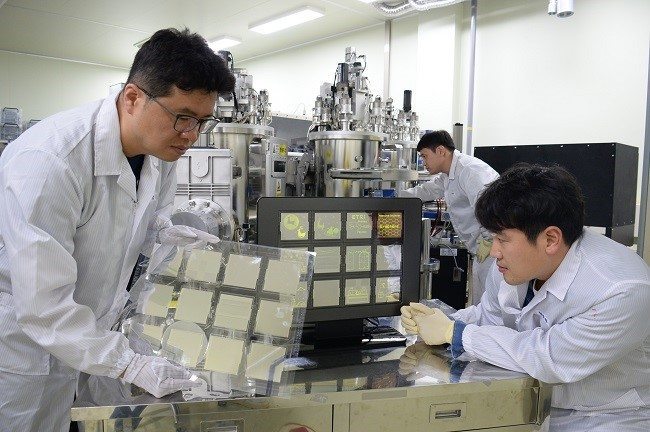

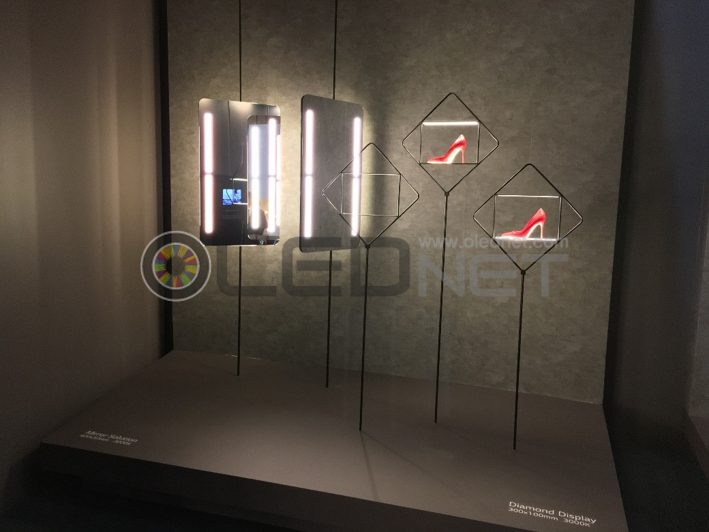

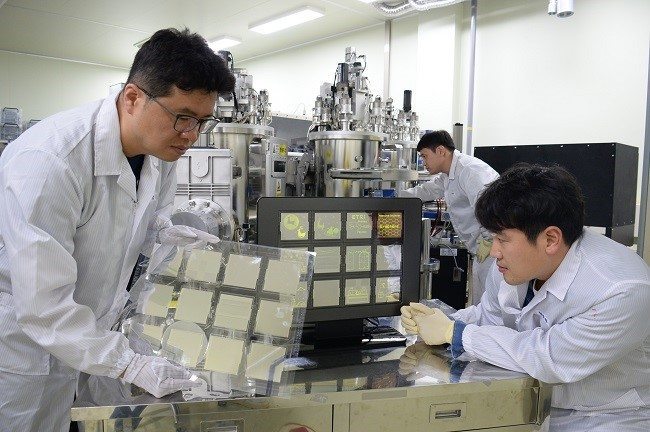

Researchers from Korea’s ETRI Institute developed a graphene transparent electrode for OLED display. Especially, they developed the process of patterning a graphene transparent electrode in exact size and shape on a large-sized substrate. Its application to smart watch requiring flexibility will be available.

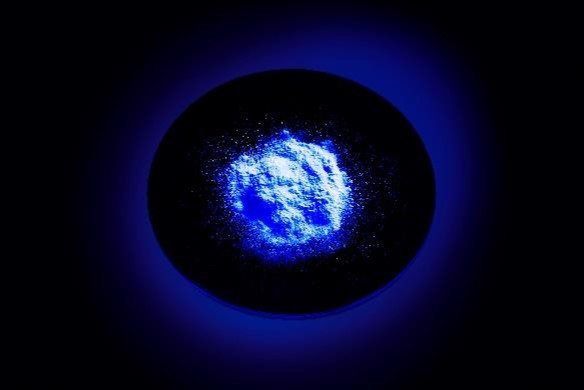

ETRI(Electronics and Telecommunications Research Institute) has succeeded in developing a display with the electrode using graphene, a dream new-material, rather than using ITO(Indium Tin Oxide) that has been often used as existing electrodes for OLED display.

The successful display substrate is the current world’s largest one of 370mm x 470mm, a 19-inch monitor in size. The thickness of graphene electrodes is less than 5nm.

ETRI expects that if the graphene is deposited on flexible substrate, thin and flexible display will be feasible. Furthermore, it will become the source technology that can be used for manufacturing wearable devices applicable to clothing or skin.

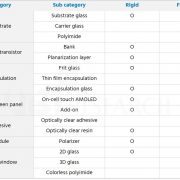

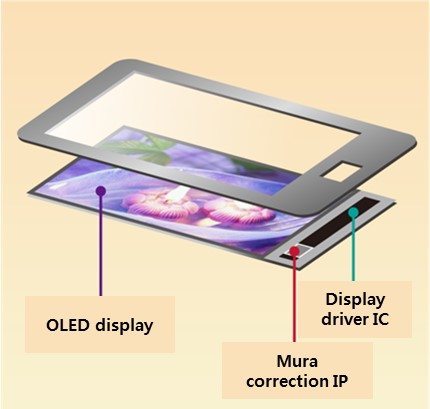

In general, OLED is stacked with substrate, ITO transparent electrode, light-emitting organic layer, and anodized aluminum. The researches replaced typical ITO with grapheme.

In particular, ITO that has been used as existing electrode has a disadvantage of being made of fragile glass. Therefore, the display manufactured with this technology will clear up the problem of fragile transparent electrode.

ETRI developed graphene growth technology and oxide technology to be applied as an OLED transparent electrode by making a large-scale substrate in collaboration with Hanwha Techwin Co.,Ltd, and secured the grapheme transparent electrode fabricating and process technology with the sheet resistance of 60Ω/m² and the transmittance of 85% applicable to OLED. Especially, ETRI developed the world’s first micro-patterning process that is absolutely required for the display process.

Using this technology, ETRI successfully lighted the world’s largest grapheme electrode OLED panel of 370mm x 470mm. The finding of this study, which was published and demonstrated at 『Graphene 2017』, the world’s largest graphene conference held in Barcelona, Spain in early April, 2016, was highly acclaimed.

The researchers started to research grapheme transparent electrodes for OLED, based on the 4-year support of the Ministry of Trade, Industry and Energy(MOTIE) and Korea Evaluation Institute of Industrial Technology(KEIT) from 2012. They successfully developed a 100mm x 100mm OLED panel last year through the recent world’s largest demonstration, starting with a 7mm x 10mm coin-sized one, at the end of 2015, leading to the higher applicability of a grapheme-based display.

They said they will develop the display with a plastic substrate instead of a glass substrate. It is possible to manufacture a wearable OLED device if grapene is attached to plastic substrate, ETRI added.

ETRI’s Flexible Device Research Head Cho, Nam-sung said “The realization of a general expectation that grapheme would be applied to OLED display is very significant. We expect it will be successfully deployed on an commercial scale through large-scale grapheme film, OLED panel technology, and flexible OLED panel technology.”

This technology is expected to edge ahead from the later competitors including China as the core technology that can further increase the level of flexible OLED displays.